Wherever there is a lot of vehicle traffic, airplane and train noise, and where there is a lot of vehicle and horn noise on main streets and highways,

Events with a loud music scene, in concert venues,

Meeting rooms,

Translation booths,

Office cubicles,

In factories,

Şişecam Acoustic Laminated Glass can be used.

Şişecam Acoustic Laminated Glass is produced by combining two or more glass plates under heat and pressure with the help of special acoustic polyvinyl butyral (PVB) layers that provide sound insulation. Thanks to PVB, acoustic laminated glass dampens sound vibrations within its structure, thus providing less sound transmission to the opposite side.

For effective sound insulation, similar precautions should be taken in the separating elements of the building such as walls, roofs and joinery.

Sound Insulation Values for Example Combinations

There is approximately 3dB difference between Şişecam Laminated Glass and Şişecam Acoustic Laminated Glass and 5 dB difference between Şişecam Colorless Float Glass and Şişecam Acoustic Laminated Glass. In acoustic insulation 10dB = 50% noise reduction.

Correction Factors

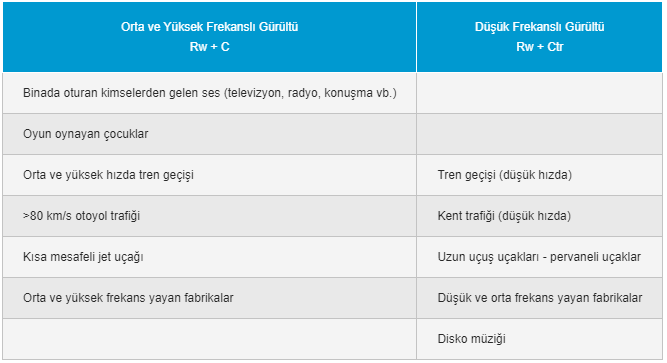

C, Ctr Spectrum adaptation values assess the suitability of construction components in relation to exposure to specific sounds.

These correction factors, called C and Ctr spectrum coherence values, reduce the sound insulation measure Rw of the component due to the noise generated according to the EN table.

A component with Rw (C, Ctr)=40 (-1,-5) has an insulation performance of 40 dB. The sound insulation is 1 dB lower for higher frequency noise sources and 5 dB lower for low frequency sources.

Noise Levels for Example Noise Sources

Quality

Şişecam Acoustic Laminated Glass is produced in accordance with TS EN ISO 12543 and TS 3539 EN 1279 standards.